Chlorine Gas Systems for Fruits and Vegetables Packing

Fruit and vegetable preservation has a long history, with ancient civilizations using techniques like sun-drying and pickling. The advent of canning in the 19th century revolutionized the industry, allowing produce to be preserved and transported over long distances (Royal Examiner, 2022).

However, as the industry grew and global trade increased, new challenges arose, including foodborne illnesses and the demand for year-round availability. Chlorine disinfection emerged as a popular method to address these risks due to its effectiveness, residual effect, and cost-effectiveness. The industry continues to evolve, exploring sustainable preservation methods and alternative disinfection approaches to meet consumer demands for safety and quality.

At Hydro Instruments, we supply food processing operations with the chlorine dioxide solutions they need to thoroughly sanitize their produce. Our collection of gas chlorination systems for food washing are designed with simplicity in mind so that they’re easy to use. In addition, we use durable, long-lasting materials in our systems to ensure they’re capable of sanitizing food contact surfaces for years to come.

To learn more about our gas chlorination systems for food washing and to find a sanitizing solution for your organization, reach out to Hydro Instruments today.

Prompting of Application

Consuming an adequate amount of fruits and vegetables is crucial for a healthy lifestyle, as recognized by organizations like the American Cancer Society (ACS) (ACS, 2020). Research has demonstrated that diets rich in fruits and vegetables offer significant health benefits, including the prevention of various diseases such as heart disease, stroke, certain types of cancer, high blood pressure, and vision problems (HSPH, n.d.).

However, ensuring the safety and quality of these produce items is paramount to protect consumers from foodborne illnesses. Inadequate disinfection, improper handling, and poor hygiene practices can lead to contamination with harmful microorganisms like bacteria, viruses, and parasites. The Centers for Disease Control and Prevention (CDC) and other health agencies have reported numerous outbreaks of foodborne illnesses associated with the consumption of fresh fruits and vegetables, with pathogens such as Salmonella, E. coli, Shigella, Hepatitis A, and Norwalk viruses posing risks to consumers’ health (CDC, 2023; APS, 2003).

Read More

To ensure the safety of fruits and vegetables, it is essential to implement robust disinfection methods that effectively reduce microbial contamination while preserving the quality and nutritional value of the produce. Chlorine disinfection has proven to be a highly effective and widely used method in the fruit and vegetable industry (Sun et al., 2012). Chlorine kills a broad spectrum of disease-causing pathogens, including bacteria, viruses, and fungi, making it an ideal choice for disinfection purposes. Furthermore, chlorine has the advantage of leaving a residual disinfectant in the water, providing ongoing protection against microbial growth and recontamination.

The application of chlorine disinfection is prompted by the need to safeguard public health and prevent foodborne illnesses associated with fresh produce consumption. By implementing proper disinfection protocols and utilizing chlorine-based solutions, growers, packagers, and distributors can significantly reduce the risk of microbial contamination and ensure the safety of fruits and vegetables for consumers.

Alternate Methods

Ozonation involves the use of ozone, a powerful oxidizing agent, to disinfect surfaces and commodities. Ozone has strong antimicrobial properties and can effectively eliminate a wide range of pathogens (Sarron et al., 2021). It offers advantages such as its ability to remove pesticide residues and its environmentally friendly nature since it breaks down into oxygen without leaving harmful residues (Sarron et al., 2021). However, ozonation requires specialized equipment and careful control of exposure levels to ensure optimal efficacy and safety.

Read More

Hydrogen peroxide is another alternative disinfection agent that has gained attention in various industries. It exhibits strong antimicrobial activity and is effective against bacteria, viruses, and fungi (Lineback et al., 2018). Hydrogen peroxide is relatively safe to use and leaves no harmful residues, as it breaks down into water and oxygen. It also has the advantage of being compatible with a wide range of materials, making it suitable for different surfaces and commodities. However, its efficacy can be influenced by factors such as concentration, contact time, and environmental conditions.

Peracetic acid, also known as peroxyacetic acid (or PAA) is a highly effective disinfectant with broad-spectrum antimicrobial activity. It is known for its rapid action and ability to inactivate various pathogens, including bacteria, viruses, and spores. Peracetic acid exhibits strong oxidizing properties and has low toxicity compared to other disinfectants. It can be used for surface disinfection as well as for the treatment of water used in processing fruits and vegetables (AMS USDA, 2000). However, it is known to be highly corrosive and can cause severe burns to the skin (NJ DOH, 2004). It is important to handle peracetic acid with caution because of its hazardous properties.

Further alternative methods for disinfecting produce have emerged, including Ultraviolet (UV) light, Non-Thermal Plasma, and Pulsed Electric Fields (PEF). UV treatment utilizes UV-C light to destroy microbial contaminants without affecting produce quality, but it has limited penetration capabilities and requires sufficient exposure time and uniform illumination. Non-thermal plasma shows promise with rapid disinfection and minimal impact on sensory attributes, but further research is needed to optimize operating parameters and assess long-term effects. PEF treatment effectively reduces microbial populations while preserving quality, but challenges remain in equipment design, treatment uniformity, and scalability for large-scale disinfection. While these methods offer innovative approaches, careful consideration is required to address their limitations and ensure their effectiveness in fruit and vegetable disinfection processes.

Equipment Selection

Hydro Instruments Products

To ensure optimal disinfection of fruits and vegetables using chlorine, Hydro Instruments offers a range of specialized products designed specifically for this purpose. The following equipment solutions are recommended to achieve efficient and controlled chlorine disinfection:

Gas Feed Systems

Hydro Instruments’ gas feed systems are designed to facilitate the controlled and efficient introduction of chlorine gas into the water used for washing, dipping, or showering produce. These systems are equipped with high-quality gas regulators, flow meters, and control valves to ensure accurate and consistent chlorine dosing. By maintaining precise control over chlorine gas dosage, the gas feed systems enable effective disinfection while minimizing wastage and ensuring the safety of operators.

Chlorine Gas Detectors

Safety is a paramount concern in chlorine disinfection processes. Hydro Instruments provides chlorine gas detectors that continuously monitor chlorine gas levels in the packing area or any other relevant space. These detectors are designed to promptly detect any potential leaks or elevated concentrations of chlorine gas, triggering alarms to alert operators. By providing early warning of hazardous conditions, the chlorine gas detectors help prevent accidents, safeguarding the well-being of personnel and ensuring a secure working environment.

Residual Analyzers

Monitoring the chlorine residual levels in the washing water is crucial to maintaining the desired disinfection efficacy. Hydro Instruments offers residual analyzers that accurately measure the concentration of free or total chlorine in real time. These analyzers provide operators with instant feedback on the chlorine residual levels, allowing them to make timely adjustments to chlorine dosing if necessary. By ensuring the proper chlorine residual concentration, the residual analyzers help optimize disinfection efficiency and maintain the desired level of microbial control.

By utilizing Hydro Instruments’ gas feed systems, chlorine gas detectors, and residual analyzers, operators can establish a comprehensive chlorine disinfection system for fruits and vegetables. These reliable and innovative equipment solutions offered by Hydro Instruments contribute to enhanced process control, increased safety, and consistent disinfection performance, ultimately ensuring the safety and quality of the produce.

Typical Setup

The water used for washing, dipping, or showering the fruit should be chlorinated and maintained at a level of 50 to 200 PPM to prevent the microbial contamination of produce at the facility. This level is easier to maintain if the water is first filtered or run through a flocculation process to remove organic material, which would otherwise bind with chlorine to form disinfection by-products with carcinogenic properties such as chloramines (CGA, 1998).

Chlorine must be continuously added to the water to replace that used in reactions with organic matter, chemicals, microorganisms and the surfaces of citrus fruits (UM, 2002). Hydro Instruments offers the necessary equipment to automatically measure free Chlorine concentrations and to add Chlorine to the water when needed.

In a typical fruit-packing plant, a stainless-steel container filled with water maintains a chlorine residual concentration of 100 PPM. A small dosing pump is used to add sodium hypochlorite to the smaller-sized trough used in the application. To monitor chlorine concentration and other chemicals (such as ozone, hydrogen peroxide, peracetic acid, and bromine), packing houses often utilize the RPH-250 Probe-type Residual Analyzer. This analysis helps determine the necessary dosing of sodium hypochlorite to maintain the required residual concentration. Fruits are usually picked up from the water by a conveyor belt and transported along a long stainless-steel trough where workers remove leaves before retrieving the fruit at the end for packing. In the case of vegetable applications, the vegetables are typically sprayed with antimicrobial agents for disinfection before being sent for packing.

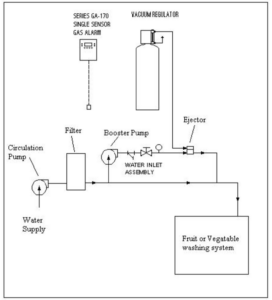

Figure 1: Gas Chlorination System for fruit & vegetable hydro cooling or washing.

In order to determine the correct capacity of Hydro Instruments chlorination equipment, the water flow must be known. Water is used as an ingredient, an initial and intermediate cleaning source, an efficient transportation conveyer of raw materials, and the principal agent used to sanitize plant machinery and areas (AEP, 2005). Because a packing house may range from a simple, on-the-farm thatched shed to an automated regional packaging line handling large tonnages of a single commercial crop, water consumption will vary. A very rough approximation of water usage during blanching is one gallon of water for each pound of produce and two gallons of water for each pound of leafy produce (Roberts/Cox, 2001). In any case, the following formulae are used to calculate the dosage needed for the washing step:

Imperial Units: Gallons Per minute (GPM) x 0.012 x Parts per Million (PPM) = Pound per Day (PPD) Metric Units: Liters Per minute (LPM) x 0.06 x Parts per Million (PPM) = Gram per Hour (g/hr)

Conclusion

Research literature clearly states that populations consuming diets rich in vegetables, fruits, and grain products have significantly lower rates of many types of cancer and diseases.

(Benedict/Leontos/Krelle-Zepponi, 1998). Thus, because appropriate practices, careful and proper packing, storage, and transport all contribute to good produce quality, steps during the post-handling of vegetables and fruits must be carefully monitored.

Chlorine plays an important role as a sanitizer for preventing decay caused by molds or bacteria on post-harvested fruits and vegetables. Sanitation is of great concern to produce handlers, not only to protect produce against post-harvest diseases but also to protect consumers from food-borne illnesses. Hydro Instruments offers the best solution for automatic Chlorine gas feeding to enable both circulating and non-circulating systems to keep the necessary residual Chlorine concentrations.

Hydro Instruments Is Proud to Offer

Liquid Chemical Feeds

Electronics

Accessories

To Order Gas Chlorination Systems for Food Washing Applications, Reach Out Today

Any food processing facility in need of a high-quality sanitizing solution can place its trust in our gas feed systems. Hydro Instruments is committed to designing and manufacturing the best technology possible to ensure our clients can adhere to Food and Drug Administration and Environmental Protection Agency standards and supply their customers with clean produce.

If you have any questions about our products and would like to purchase a chlorine solution for your food-washing operations, call us today.

References

- Canning history: How canned food revolutionized society (2022, July 30). https://royalexaminer.com/canning-history-how-canned-food-revolutionized-society/

- Rock, C. L., Thomson, C., Gansler, T., Gapstur, S. M., McCullough, M. L., Patel, A. V., Andrews, K. S., Bandera, E. V., Spees, C. K., Robien, K., Hartman, S., Sullivan, K., Grant, B. L., Hamilton, K. K., Kushi, L. H., Caan, B. J., Kibbe, D., Black, J. D., Wiedt, T. L., … Doyle, C. (2020). American Cancer Society guideline for Diet and physical activity for cancer prevention. CA: A Cancer Journal for Clinicians, 70(4), 245–271. https://doi.org/10.3322/caac.21591

- Vegetables and fruits. The Nutrition Source. (2021, March 3). https://www.hsph.harvard.edu/nutritionsource/what-should-you-eat/vegetables-and- fruits/

- Centers for Disease Control and Prevention. (2023, June 20). Fruit and vegetable safety. Centers for Disease Control and Prevention. https://www.cdc.gov/foodsafety/pdfs/fruit-veggie-safety-h.pdf

- ScienceDaily. (2003, January 28). More people are getting sick from eating fresh fruits. ScienceDaily. https://www.sciencedaily.com/releases/2003/01/030128080057.htm

- Sun, S.-H., Kim, S.-J., Kwak, S.-J., & Yoon, K.-S. (2012). Efficacy of sodium hypochlorite and acidified sodium chlorite in preventing browning and microbial growth on fresh-cut produce. Preventive Nutrition and Food Science, 17(3), 210–216. https://doi.org/10.3746/pnf.2012.17.3.210

- Sarron, E., Gadonna-Widehem, P., & Aussenac, T. (2021). Ozone treatments for preserving fresh vegetables quality: A critical review. Foods, 10(3), 605. https://doi.org/10.3390/foods10030605

- Lineback, C. B., Nkemngong, C. A., Wu, S. T., Li, X., Teska, P. J., & Oliver, H. F. (2018). Hydrogen peroxide and sodium hypochlorite disinfectants are more effective against Staphylococcus aureus and Pseudomonas aeruginosa biofilms than quaternary ammonium compounds. Antimicrobial Resistance & Infection Control, 7(1). https://doi.org/10.1186/s13756-018-0447-5

- Peracetic acid technical report. (2000, November 3). https://www.ams.usda.gov/sites/default/files/media/Peracetic%20Acid%20Technical%2 0Report%20Handling.pdf

- Matthew Ranelli, A. A. (1998, February 18). Chlorine and chloramines in drinking water. https://www.cga.ct.gov/PS98/rpt%5Colr%5Chtm/98-R- 0180.htm#:~:text=Chlorine%20reacts%20with%20organic%20compounds,such%20as%20 bromodichloromethane%20and%20chloroform.

- Safety and quality of fresh fruit and vegetables – UNCTAD. (n.d.). https://unctad.org/system/files/official-document/ditccom200616_en.pdf

- Boyer, R. R., Pellan, P., & Conforti, F. (2018). Freezing fruits and vegetables – Virginia tech. https://lynchburg.ext.vt.edu/content/dam/lynchburg_ext_vt_edu/348-596_pdf.pdf%20freezing.pdf

- The Journal of Extension (JOE). (n.d.). Increasing fruit and vegetable consumption among middle school students: Implementing the 5-A-day program. A. https://archives.joe.org/joe/1998au

Peroxyacetic acid hazard summary – the official website for the state … (2004, October). https://www.nj.gov/health/eoh/rtkweb/documents/fs/1482.pdf