Chlorine Gas in Swimming Pools

Background

Brief History

Swimming pools provide a refreshing and enjoyable experience, but maintaining proper water chemistry is crucial for creating a safe and hygienic environment. Chlorine has long been recognized as a highly effective disinfectant for swimming pools. This paper examines the significance of chlorine in pool disinfection and introduces Hydro Instruments as a leading provider of chlorine disinfection equipment.

Prompting of Application

Maintaining proper water chemistry is essential in swimming pools to ensure hygienic conditions. Chlorine plays a vital role in pool disinfection by effectively killing microorganisms and bacteria that thrive in water (The Pool Butler, 2023). The breakdown of chlorine gas in water releases hypochlorous acid and hypochlorite ions, which destroy the cell walls and enzymes of microorganisms (Lenntech, n.d.). The significance of chlorine application in maintaining a safe and inviting pool environment is emphasized.

Chlorine Disinfection: The Key to Pool Hygiene

Importance of Disinfection

Proper disinfection is of paramount importance in maintaining the hygiene and safety of swimming pools. Untreated pool water creates a breeding ground for harmful microorganisms, including bacteria, viruses, and algae. These microorganisms can pose serious health risks to swimmers, leading to waterborne diseases, gastroenteritis, and ear, nose, and throat infections (Better Health Channel, 2003). Moreover, the presence of these contaminants can degrade water quality, resulting in cloudy or foul-smelling water, significantly affecting swimmers’ experiences in the pool (Eco Outdoor, 2018).

To ensure a safe and inviting swimming environment, it is essential to implement effective disinfection practices. Disinfection prevents the proliferation of microorganisms, thus reducing the risk of infections and promoting good hygiene. By maintaining proper disinfection, swimming pool owners and operators fulfill their responsibility of safeguarding the health and well-being of swimmers.

Chlorine’s Mechanism of Action:

Chlorine, in its various forms, is a highly effective disinfectant for swimming pools. When added to pool water, chlorine undergoes chemical reactions that destroy microorganisms and bacteria. Chlorine gas combines with water to form hypochlorous acid (HOCl) and hypochlorite ions (OCl-), collectively known as “free chlorine” (Safe Drinking Water Foundation, 2021).

Hypochlorous acid penetrates microorganism cell walls, attacking and destroying them (Nizer et al., 2020). Hypochlorite ions also contribute to disinfection by releasing active chlorine species that oxidize and eliminate microorganisms (Gray, 2013). This dual action of hypochlorous acid and hypochlorite ions ensures thorough disinfection, preventing the growth of bacteria, viruses, and algae in the pool water.

It’s important to monitor chlorine levels regularly, considering factors like pH, temperature, and other compounds present in the water (Centers for Disease Control and Prevention [CDC], 2022; Orenda Technologies, 2023). This ensures optimal disinfection efficacy and helps maintain a clean and sanitary swimming environment.

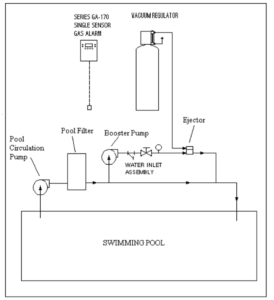

Figure 1: Swimming Pool Gas Chlorination Installation

Equipment Selection for Chlorine Disinfection

Hydro Instruments Product Range:

Hydro Instruments has established itself as a trusted provider of high-quality chlorine disinfection equipment specifically designed for swimming pools. Our extensive product range encompasses a variety of solutions tailored to meet the unique requirements of pool owners and operators. From gas feed systems to monitoring and control equipment, Hydro Instruments offers a comprehensive selection of products to ensure effective and efficient chlorine disinfection.

Among the offerings are gas feed systems that play a crucial role in accurately and safely introducing chlorine gas into the pool water. These systems are designed with precision and reliability in mind, allowing for precise control of chlorine dosing. Hydro Instruments’ gas feed systems are equipped with advanced features such as flow meters, pressure regulators, and automatic shut-off valves, ensuring precise and consistent chlorine dosage. By incorporating these systems into pool operations, pool owners can achieve optimal disinfection results while maintaining the safety of swimmers.

Monitoring and Control Equipment:

Maintaining optimal chlorine levels in pool water is essential for effective disinfection. Hydro Instruments recognizes the importance of monitoring and control equipment in achieving this goal. Our range of residual analyzers and chlorine gas detectors for swimming pools enables operators to accurately measure chlorine levels and ensure the safety of pool environments.

Residual analyzers offer real-time monitoring of chlorine concentrations, allowing for immediate adjustments to maintain the desired disinfectant levels. Hydro Instruments’ residual analyzers are designed for accuracy and reliability, providing precise measurements even in challenging pool conditions. By incorporating these analyzers into pool maintenance routines, operators can proactively manage chlorine levels and address any deviations promptly, ensuring the effectiveness of disinfection while minimizing the risk of under- or over-chlorination.

Chlorine gas detectors are another essential component of pool safety. These devices continuously monitor chlorine gas concentrations in the air surrounding the storage and handling areas. Hydro Instruments’ chlorine gas detectors are equipped with advanced sensing technologies, providing reliable and early detection of any gas leaks or deviations from safe levels. This enables prompt action to mitigate potential hazards, ensuring the safety of pool staff and maintaining a secure environment for swimmers.

Pool experts recommend adding gaseous chlorine just after filtration using a chemical feeder (see diagram 1). Each pool has its own Chlorine demand, which is the amount of Chlorine needed to destroy contaminants that are present.

Additionally, each pool has a different capacity. Other factors, such as the water balance and particular pH, determine how much Chlorine has to be injected. What we must consider is the Chlorine residual that we want to maintain in the pool water. The Centers for Disease Control and Prevention recommends a free chlorine concentration of at least 1 ppm in pools (CDC, 2022).

The following table is an approximate calculation of which Hydro Instruments chlorinator is appropriate to be installed. The following table is built upon the following conversion factor formulae, which roughly estimate the Chlorine dosage rate as a factor of the surrounding temperature of the pool and its size. Estimates are done assuming that all the water circulates once every 4 hours and that water evaporates at a constant rate that depends on the water temperature (the higher the temperature, the higher the dosage). This formula works for temperatures between (71 – 95) °F. (these are only estimates):

| Pool Size (Gallons) | Temperature | Dosage Rate | Hydro Instruments |

| (x 1000) | (Degrees | (Pounds Per Day) | Chlorinator |

| Fahrenheit) | |||

| 20 | 72 | 3.57 | Series 500 (4PPD) |

| 78 | 4.54 | Series 500 (10PPD) | |

| 85 | 6.67 | Series 500 (10PPD) | |

| 40 | 72 | 7.14 | Series 500 (10PPD) |

| 78 | 9.1 | Series 500 (10PPD) | |

| 85 | 13.33 | Series 500 (25PPD) | |

| 75 | 72 | 13.4 | Series 500 (25PPD) |

| 78 | 17.05 | Series 500 (25PPD) | |

| 85 | 25 | Series 500 (50PPD) Recommended | |

| 100 | 72 | 17.86 | Series 500 (25PPD) |

| 78 | 22.73 | Series 500 (25PPD) | |

| 85 | 33.33 | Series 500 (50PPD) | |

| 150 | 72 | 26.79 | Series 500 (50PPD) |

| 78 | 34.1 | Series 500 (50PPD) | |

| 85 | 50 | Series 500 (100PPD) | |

| 200 | 72 | 35.71 | Series 500 (100PPD) |

| 78 | 45.45 | Series 500 (100PPD) | |

| 85 | 66.67 | Series 500 (100PPD) | |

| 300 | 72 | 53.57 | Series 500 (100PPD) |

| 78 | 68.18 | Series 500 (100PPD) | |

| 85 | 100 | Series 200 (200PPD) Recommended | |

| 500 | 72 | 89.29 | Series 500 (100PPD) |

| 78 | 113.64 | Series 200 (200PPD) | |

| 85 | 166.67 | Series 200 (200PPD) |

PPD (Pounds Per day) = Pool Volume (in Gallons) / 200(100 – Temperature (in Fahrenheit))

Using the same pump used to recirculate the water can usually create the vacuum needed in order for the Venturi ejector to work. This depends on the water re-circulation flow rate; the local law dictates that all the water in the pool must pass through the filter in a certain amount of time, typically between 30 minutes and 6 hours (Harris, 2002).

Further Considerations

There are other additional concerns that must be taken into account when using any gas-feeding equipment.

- Papers have been published affirming that high Chlorine concentrations might affect swimmers’ respiratory systems.

- On the other hand, the main hazard of using Chlorine in pools relies on the person in charge of adding Chlorine to the pool.

- Hypochlorous Acid may combine with Ammonia (found in urine) to produce various chloramines. Chloramines can irritate the skin and eyes and have an unpleasant odor (Harris, 2002).

However, Hydro Instruments makes safety the highest concern. We’re aware of the careful monitoring of using any kind of disinfectant in pools. To that end, the electronic equipment offered by Hydro Instruments enables automatic feeding for chlorine residuals.

Why Choose Hydro Instruments’ Chlorine Gas Feed Systems for Pools?

Durable and Longlasting

Our chlorination systems for swimming pools are built with durability, longevity, and corrosion resistance in mind to maintain years of consistent water quality. Hydro Instruments’ systems are engineered to withstand harsh environmental conditions, which greatly reduces maintenance demands over time. This durability contributes directly to reliable swimming pool sanitation and extended equipment lifespan.

Quality Material Selection

To ensure our chlorination products are as durable as possible, we don’t cut corners when it comes to material selection. Material integrity helps our systems stay in top shape so that they can resist degradation while remaining in contact with chemicals. The quality of each component — from the pipe to the tank — reinforces system reliability in demanding water treatment applications.

Careful Assembly and Testing

Hydro Instruments goes the extra mile in assembly to eliminate potential failures and performance issues. Each control valve is calibrated for accurate chlorine delivery, promoting consistent water purification. These quality checks are crucial for keeping our systems leak-free and capable of handling liquid feed and gaseous chlorine flow for years.

Simple and Easy to Operate

With decades of design experience, we strive to create user-friendly systems to improve day-to-day functionality for pool technicians and operators. Clear interfaces and intuitive controls simplify dosing adjustments and monitoring. These features make it easy to maintain a safe and clean swimming environment without extensive training or technical expertise.

If You’re Searching for Advanced Gas Feed Systems for Swimming Pools, Call Hydro Instruments

Whether you need a reliable chlorine analyzer for swimming pools, a gas alarm to mitigate emergencies, or other high-quality gas or liquid feed equipment, you’ll find what you need in our selection.

Reach out today to learn more about our chlorine treatment for swimming pools and the other trusted accessories and electronics we offer.